Product Introduction

Chinese Standard

American Standard

European Standard

German Standard

Chinese Standard

American Standard

European Standard

| Product Name | Standard | Stee I Grade |

| Seamless steel tubes for pressure purpose | EN 10216-1 EN 10216-2 |

P195TR1/P235TR1/P265TR1 P195GH/P235GH/P265GH |

| Steel tubes for precision application | EN 10305 | E215/E235/E355 |

German Standard

Product Manufacturing Process

Tube blank

Inspection (spectral detection, surface inspection, and dimensional inspection)

Sawing

Perforation

Thermal inspection

Pickling

Grinding inspection

Lubrication

Cold drawing

Lubrication

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

Normalization

Performance test (mechanical property, impact property, hardness, flattening, flaring, and flanging)

Straightening

Tube cutting

Non-destructive testing (eddy current, ultrasonic, and magnetic flux leakage)

Hydrostatic test

Product inspection

Packaging

Warehousing

Advantages of Seamless Steel Pipe

Light Weight

Seamless steel pipe is light weight, its weight is only 1/5 of square steel.

Corrosion Resistance

Seamless steel pipe is resistant to corrosion of acid, alkali, salt and atmospheric environment, high temperature, good impact resistance and fatigue resistance.

Tensile Strength

The tensile strength of seamless steel pipe is more than 8-10 times that of ordinary steel, and the modulus of elasticity is better than that of steel.

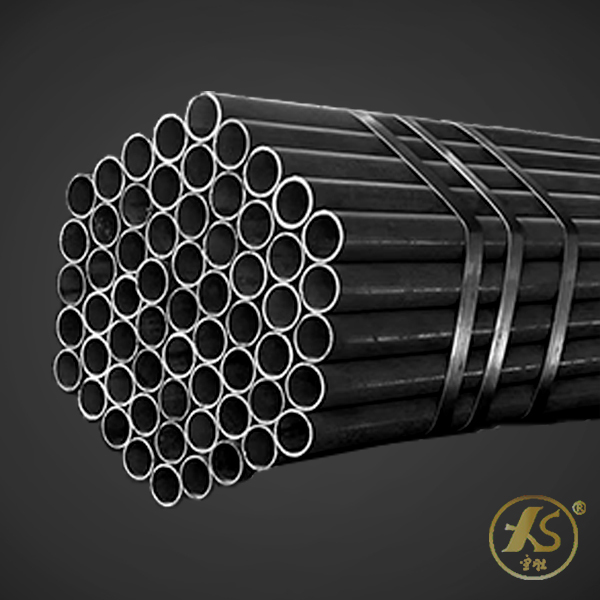

Detail Display

![Stainless steel pipes, brushed metal on white background.

Digitally generated hi-res 3D image.

[b]Free transparency mask[/b] (alpha channel):[b] [url=http://www.grafik3d.com/istockphoto/alpha/stainless_steel_pipes3_alpha.tif]»Download«[/url] [/b]](http://www.xshmetal.com/uploads/Steel-Tube-3.jpg)

Bright and clean inside and out

The surface will appear after polishing Bright and flat

Uniform wall thickness

Cut according to the customer's requirements, and the section is neat

Customization support

Support customization of multiple specificationsand materials