Short Lead Time for A 106 Gr B - Seamless medium carbon steel boiler and superheater tubes – Xuansheng Detail:

Seamless medium carbon steel boiler and superheater tubes

| Product material | A1/C |

| Product specification | |

| Product applied standard | ASTM A210 |

| Delivery status | |

| Finished products package | Steel belt hexagonal package/plastic film/woven bag/sling package |

Product Manufacturing Process

![]()

Tube blank

Inspection (spectral detection, surface inspection, and dimensional inspection)

![]()

Sawing

![]()

Perforation

![]()

Thermal inspection

![]()

Pickling

![]()

Grinding inspection

![]()

Lubrication

![]()

Cold drawing

![]()

Lubrication

![]()

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

![]()

Normalization

![]()

Performance test (mechanical property, hardness, flattening, flaring, and flanging)

Straightening

![]()

Tube cutting

![]()

Non-destructive testing (eddy current or ultrasonic)

![]()

Hydrostatic test

![]()

Product inspection

![]()

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine, sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Outside micrometer, tube micrometer, dial bore gage, vernier caliper, chemical composition detector, spectral detector, tensile testing machine, Rockwell hardness tester, impact testing machine, eddy current flaw detector, ultrasonic flaw detector, and hydrostatic testing machine

Product Applications

Boiler tubes and boiler flue tubes

Seamless Tubing Manufacturing

Knowing that distinction can also help in determining which tubing is best for a given application, welded or seamless. The method of manufacturing welded and seamless tubing is evident in their names alone. Seamless tubes are as defined – they do not have a welded seam. The tubing is manufactured through an extrusion process where the tube is drawn from a solid stainless steel billet and extruded into a hollow form. The billets are first heated and then formed into oblong circular molds that are hollowed in a piercing mill. While hot, the molds are drawn through a mandrel rod and elongated. The mandrel milling process increases the molds length by twenty times to form a seamless tube shape. Tubing is further shaped through pilgering, a cold rolling process, or cold drawing.

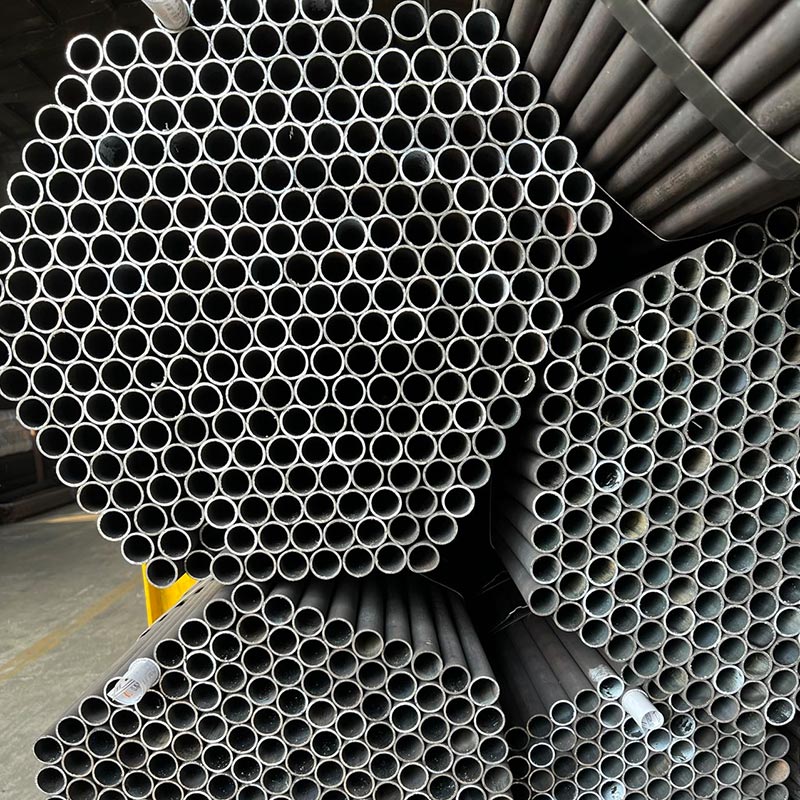

Product detail pictures:

Related Product Guide:

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for Short Lead Time for A 106 Gr B - Seamless medium carbon steel boiler and superheater tubes – Xuansheng, The product will supply to all over the world, such as: South Africa, Kenya, Philippines, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.