Video

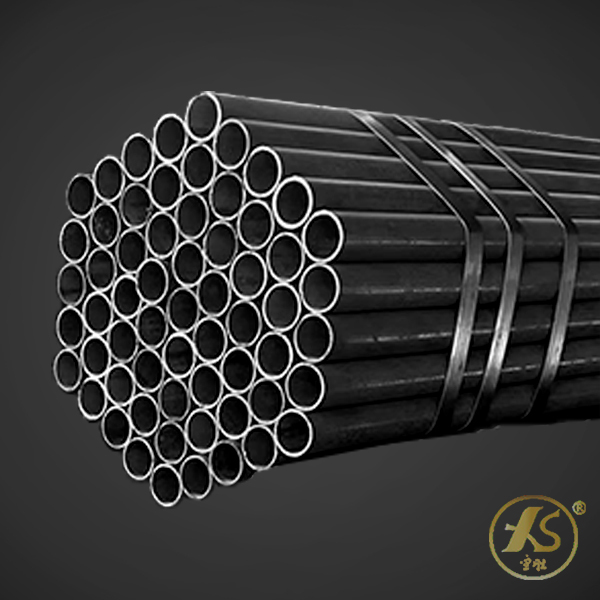

Seamless steel tubes for structural purpose

Product Manufacturing Process

Tube blank

Inspection (spectral detection, surface inspection, dimensional inspection, and macro examination)

Sawing

Perforation

Thermal inspection

Pickling

Grinding inspection

Pickling

Lubrication

Cold drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

Annealing or cold drawing or stress relieved or full annealing (selected according to customer’s requirements)

Performance test (mechanical property, impact power test of Q460 according to customer’s requirements)

Straightening

Tube cutting

Product inspection

Immersion of anti-corrosive oil

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine/sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Product Applications

Why choose us

We provide seamless mechanical steel tubing products designed to thrive in demanding, high-stress applications. You find these products in automotive components where performance depends on reliability and quality. In addition, you find your seamless mechanical steel tubing for industrial applications - ranging from bearings to cylinders and gears - where toughness is essential for functionality. Oil and gas exploration is another common use for our seamless mechanical tubing, where durability and component life below the Earth's surface is paramount.

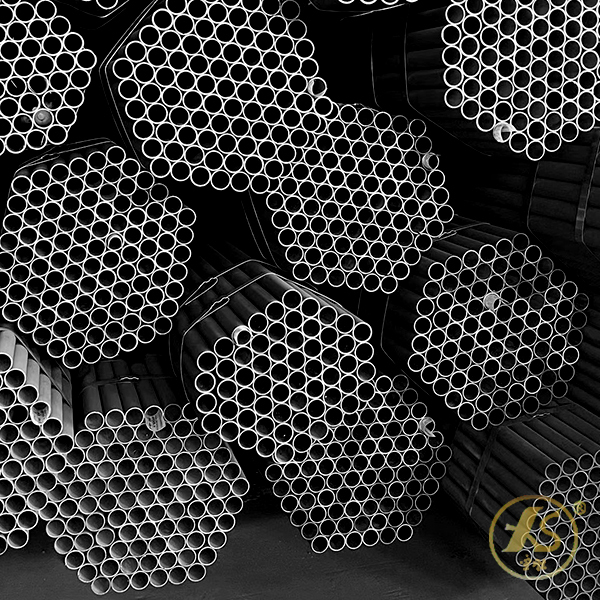

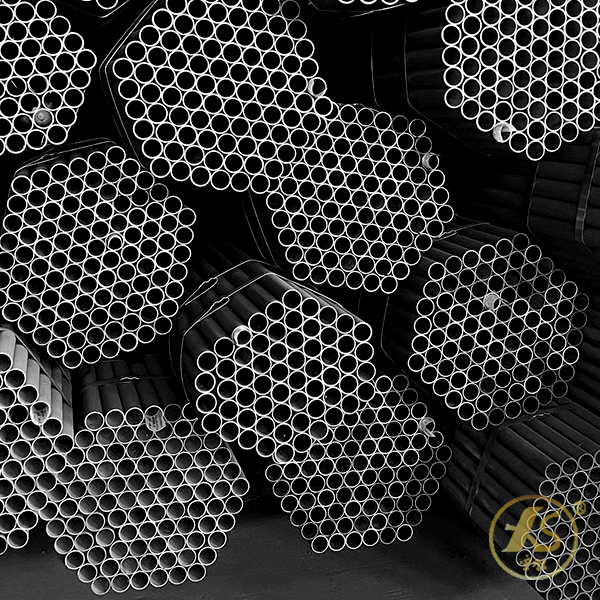

Package of carbon steel seamless pipe

Plastic caps plugged at the two sides of pipe ends

Should be avoided by the steel strapping and transport damage

Bundled sians should be uniform and consistent

The same bundle(batch) of steel pipe should be came from the same furnace

The steel pipe has the same furnace number,the same steel gradethe same specification