Video

Seamless steel tubes for liquid service

Product Manufacturing Process

Tube blank

Inspection (spectral detection, surface inspection, dimensional inspection, and macro examination)

Sawing

Perforation

Thermal inspection

Pickling

Grinding inspection

Pickling

Lubrication

Cold drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

Annealing or cold drawing or stress relieved or full annealing (selected according to customer’s requirements)

Performance test (mechanical property, impact power test of Q345 and Q460 series according to customer’s requirements)

Straightening

Tube cutting

Product inspection

Immersion of anti-corrosive oil

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine/sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Product Applications

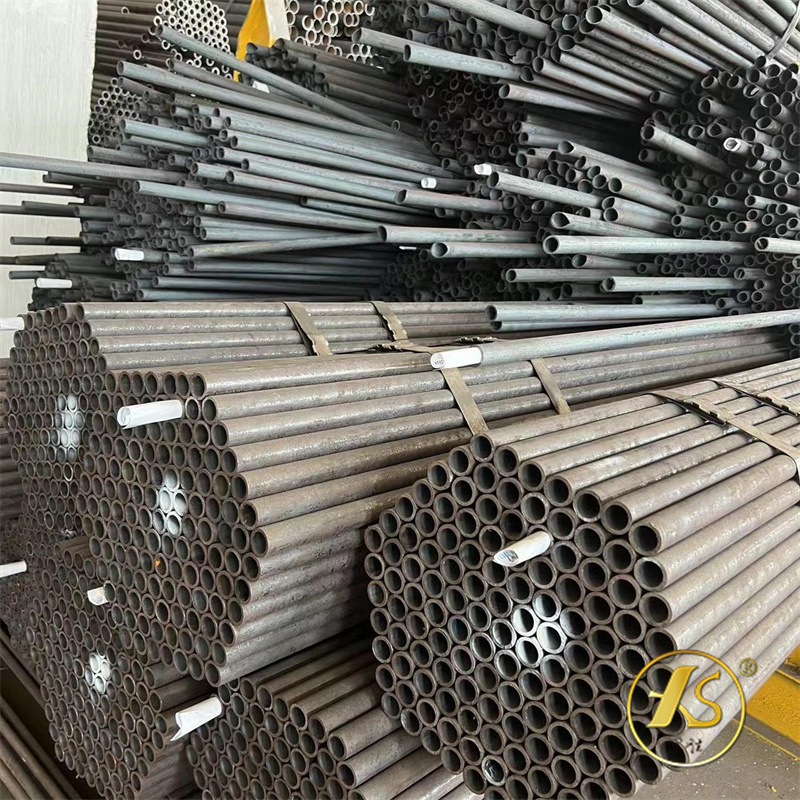

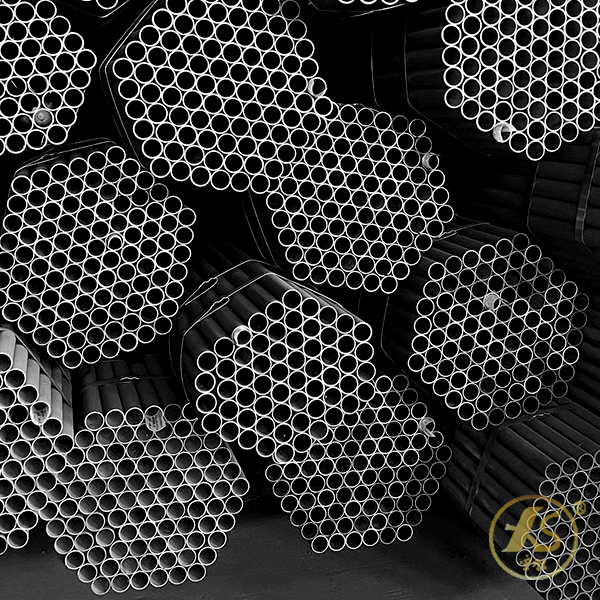

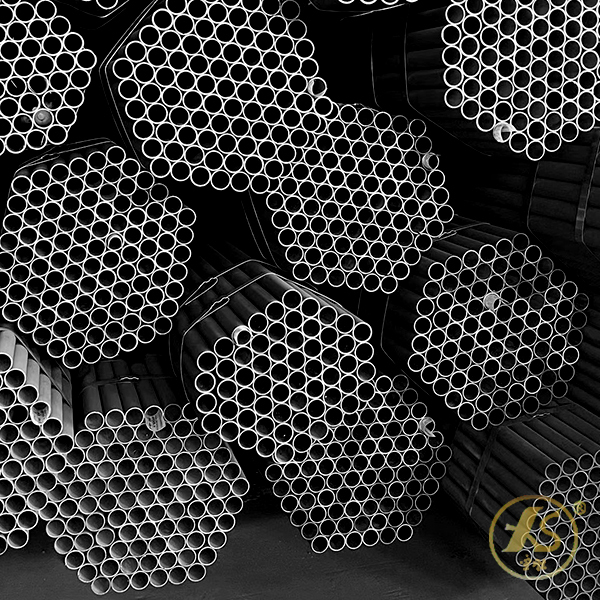

Package of carbon steel seamless pipe

Plastic caps plugged at the two sides of pipe ends

Should be avoided by the steel strapping and transport damage

Bundled sians should be uniform and consistent

The same bundle(batch) of steel pipe should be came from the same furnace

The steel pipe has the same furnace number,the same steel gradethe same specification