Quality Inspection for Excavator Tooth Pin - Seamless carbon steel boiler tubes for high pressure service – Xuansheng Detail:

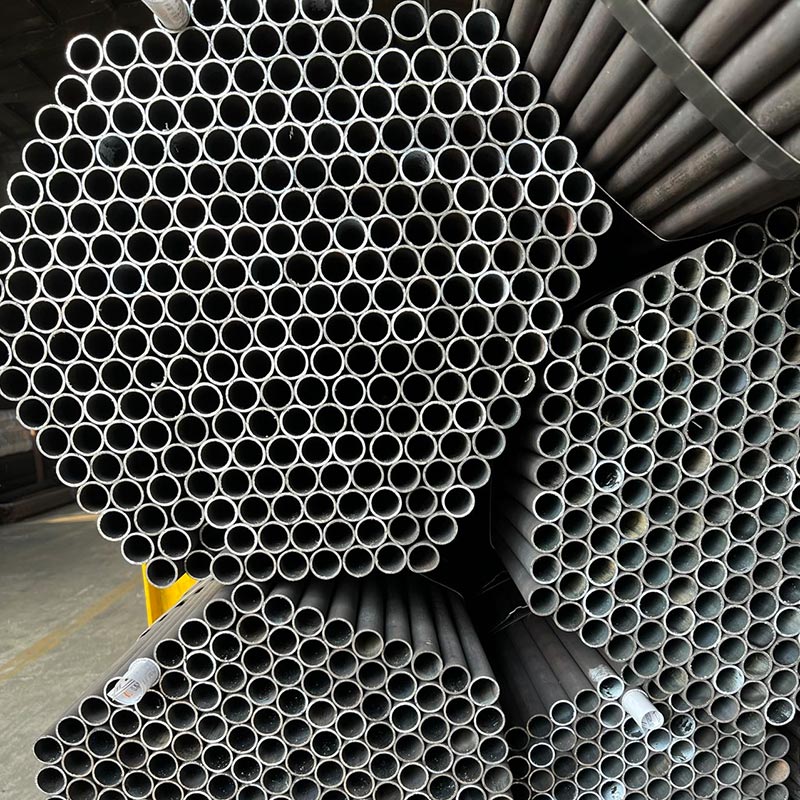

Seamless carbon steel boiler tubes for high pressure service

| Product material | SA192 |

| Product specification | |

| Product applied standard | ASTM A192 |

| Delivery status | |

| Finished products package | Steel belt hexagonal package/plastic film/woven bag/sling package |

Product Manufacturing Process

![]()

Tube blank

Inspection (spectral detection, surface inspection, dimensional inspection, and macro examination)

![]()

Sawing

![]()

Perforation

![]()

Thermal inspection

![]()

Pickling

![]()

Grinding inspection

![]()

Annealing

![]()

Pickling

![]()

Lubrication

![]()

Cold drawing

![]()

Annealing

![]()

Pickling

![]()

Lubrication

![]()

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

![]()

Normalization

![]()

Performance test (mechanical property, impact property, metallographic, flattening, flaring, and hardness)

Straightening

![]()

Tube cutting

![]()

Non-destructive testing (eddy current, and ultrasonic)

![]()

Hydrostatic test

![]()

Product inspection

![]()

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine/sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Outside micrometer, tube micrometer, dial bore gage, vernier caliper, chemical composition detector, spectral detector, tensile testing machine, Rockwell hardness tester, impact testing machine, eddy current flaw detector, ultrasonic flaw detector, and hydrostatic testing machine

Product Applications

High-pressure seamless carbon steel boilers with minimum wall thickness and superheaters

Why choose us

We produce seamless mechanical steel tubing, in the hot-rolled condition, close to your finished part size, which makes it very competitive compared to other forging or machining processes. You may also purchase tubes in sizes recommended to clean up at finished part dimensions, which allows for optimum material utilization.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Quality Inspection for Excavator Tooth Pin - Seamless carbon steel boiler tubes for high pressure service – Xuansheng, The product will supply to all over the world, such as: Canada, Hungary, France, We integrate design, manufacture and export together with more than 100 skillful workers, strict quality controlling system and experienced technology.We keep long term business relationships with wholesaler and distributors form more than 50 countries, such as USA, UK, Canada, Europe and Africa etc.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.