Popular Design for Seamless Mechanical Tubing - Seamless steel tubes and pipes for high pressure boiler – Xuansheng Detail:

Seamless steel tubes and pipes for high pressure boiler

| Product material | 20G/ 25MnG/ 12CrMoG /12Cr2MoG/ 15CrMoG/ 12Cr1MoG/ 10Cr9MoIVNbN |

| Product specification | |

| Product applied standard | GB/T5310-2017 |

| Delivery status | |

| Finished products package | Steel belt hexagonal package/plastic film/woven bag/sling package |

Product Manufacturing Process

![]()

Tube blank

Inspection (spectral detection, surface inspection, and dimensional inspection)

![]()

Sawing

![]()

Perforation

![]()

Thermal inspection (alloy steel requires heat treatment)

![]()

Pickling

![]()

Grinding inspection

![]()

Lubrication

![]()

Cold drawing

![]()

Lubrication

![]()

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

![]()

Normalization/Normalization + tempering

![]()

Performance test (mechanical property, metallographic, impact property, hardness, flattening, and flaring)

Straightening

![]()

Tube cutting

![]()

Non-destructive testing (eddy current, and ultrasonic)

![]()

Hydrostatic test

![]()

Product inspection

![]()

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine, sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Outside micrometer, tube micrometer, dial bore gage, vernier caliper, chemical composition detector, spectral detector, tensile testing machine, Rockwell hardness tester, impact testing machine, eddy current flaw detector, ultrasonic flaw detector, and hydrostatic testing machine

Product Applications

High pressure steam boilers and pipelines

Advantage

Precision steel pipe in the inheritance of the advantages of seamless steel pipe at the same time, but also has some of its own characteristics. With precision manufacturing ring parts, can improve material utilization, simplify the manufacturing process, save materials and processing hours, such as rolling bearing rings, jack sets, etc., has been widely used to manufacture precision steel tubes. The promotion of the application of precision seamless tube to save steel, improve processing efficiency, reduce the processing process or equipment investment has important significance, can save costs and processing hours, improve production and material utilization, while helping to improve product quality, reduce costs, to improve economic efficiency has important significance. Generally, the industries that require high precision use seamless precision tubes, and those that do not require precision mostly use seamless tubes, after all, the price of precision seamless tubes with the same specifications is higher than that of seamless tubes.

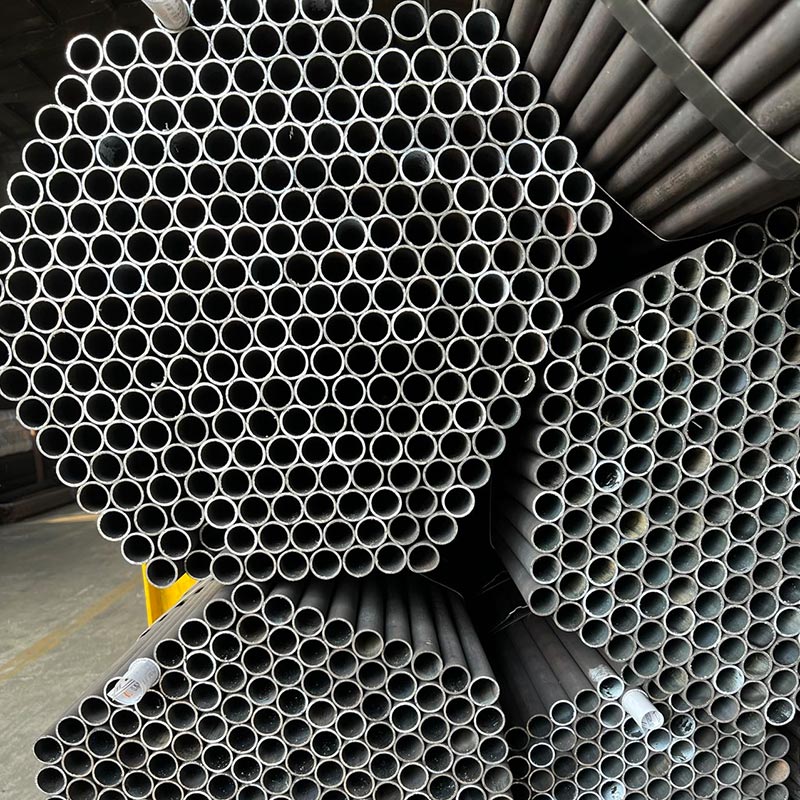

Product detail pictures:

Related Product Guide:

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Popular Design for Seamless Mechanical Tubing - Seamless steel tubes and pipes for high pressure boiler – Xuansheng, The product will supply to all over the world, such as: Paris, Saudi Arabia, Grenada, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!