Video

Petroleum and natural gas industries-Steel pipe for pipeline transportation systems

Product Manufacturing Process

Tube blank

Inspection (spectral detection, surface inspection, dimensional inspection, and macro examination)

Sawing

Perforation

Thermal inspection

Pickling

Grinding inspection

Pickling

Lubrication

Cold drawing

Lubrication

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

Normalization

Performance test (mechanical property, impact property, hardness, flattening, flaring, and flanging)

Straightening

Tube cutting

Non-destructive testing (eddy current, and ultrasonic)

Spectral detection

Drift diameter

Hydrostatic test

Groove

Product inspection

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine/sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Product Applications

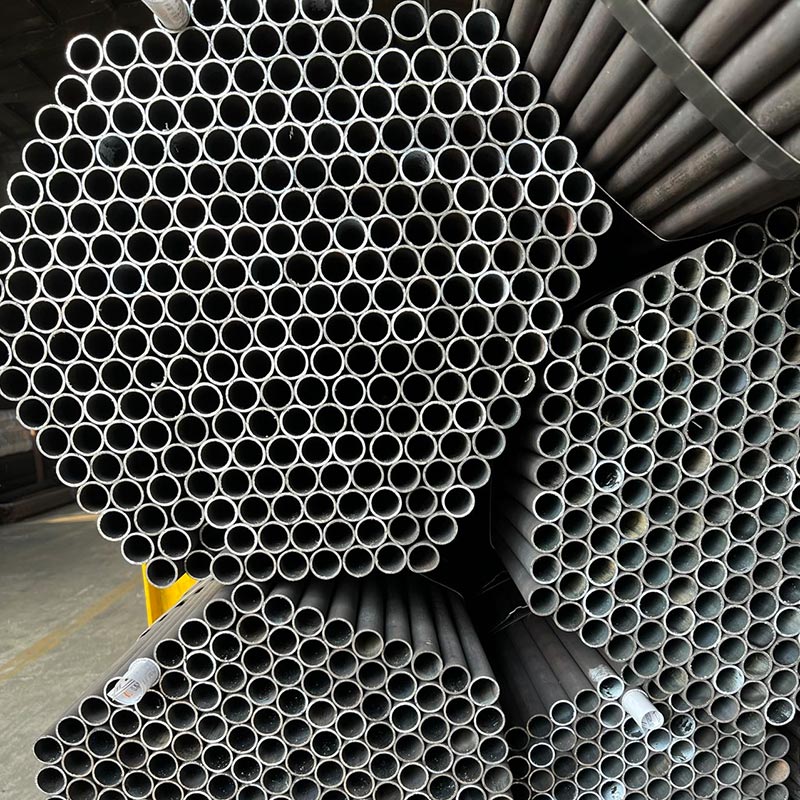

Seamless steel tubes

Seamless steel tubes for general use are also supplied according to chemical composition and mechanical properties and hydrotesting. Seamless steel tubes subjected to fluid pressure should pass the hydraulic test. Special Liaocheng seamless steel pipe for boiler, geological exploration, bearing, acid resistance, etc.

Such as petroleum geological drilling tubes, petrochemical cracking tubes, boiler tubes, bearing tubes, automotive, tractor, aviation high-precision structural steel tubes.

Testing:

1.Observe the logo, specification, factory name and related information on the steel pipe.

2. Check the quality certificate provided by the seamless steel pipe manufacturer.

3.When buying seamless steel pipe, observe whether there are cracks, scars and other hard injuries on the surface of the steel pipe.

4. Observe whether the paint on the surface of the seamless steel pipe is even.

5. In order to avoid purchasing inferior products, try to purchase products from large and well-known brand companies.

Package of carbon steel seamless pipe

Plastic caps plugged at the two sides of pipe ends

Should be avoided by the steel strapping and transport damage

Bundled sians should be uniform and consistent

The same bundle(batch) of steel pipe should be came from the same furnace

The steel pipe has the same furnace number,the same steel gradethe same specification