OEM Customized Teeth For Front Loader Bucket - Steel tubes for precision application – Xuansheng Detail:

Steel tubes for precision application

| Product material | E215/E235/E355 |

| Product specification | |

| Product applied standard | EN 10305 |

| Delivery status | |

| Finished products package | Steel belt hexagonal package/plastic film/woven bag/sling package |

Product Manufacturing Process

![]()

Tube blank

Inspection (spectral detection, surface inspection, and dimensional inspection)

![]()

Sawing

![]()

Perforation

![]()

Thermal inspection

![]()

Pickling

![]()

Grinding inspection

![]()

Lubrication

![]()

Cold drawing

![]()

Lubrication

![]()

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

Cold drawing/hard +C or cold drawing/soft +LC or cold drawing and stress relieved +SR or annealing +A or normalization +N (selected according to customer’s needs)

![]()

Performance test (mechanical property, impact property, flattening, and flaring)

Straightening

![]()

Tube cutting

![]()

Non-destructive testing

![]()

Hydrostatic test

![]()

Product inspection

Immersion of anti-corrosive oil

![]()

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine/sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Outside micrometer, tube micrometer, dial bore gage, vernier caliper, chemical composition detector, spectral detector, tensile testing machine, Rockwell hardness tester, impact testing machine, eddy current flaw detector, ultrasonic flaw detector, and hydrostatic testing machine

Product Applications

Chemical equipment, ships, pipelines, automotive parts, and mechanical design applications

Seamless steel pipe

Seamless steel pipe (SMLS) is formed by drawing a solid billet over a piercing rod to create the hollow shell, without welding or seam. It is suitable for bending and flanging. The most advantage is increasing the ability of withstanding higher pressure. So it is widely used for boiler and pressure vessel, automotive area, oil well, and equipment components.

Seamless steel pipe can be cut, threaded or grooved. And the coating method includes black / red lacquer, varnish painting, hot dip galvanization, etc.

Cold Drawn Mill:

Cold drawn mill is used for producing small size pipe. There are several times of cold forming process, so yield strength and tensile strength values increase, while elongation and toughness values decrease. A heat treatment must to be applied for each cold forming operation.

Comparing hot rolled pipe, cold drawn pipe maintains precise dimension, smooth surface and shining appearance.

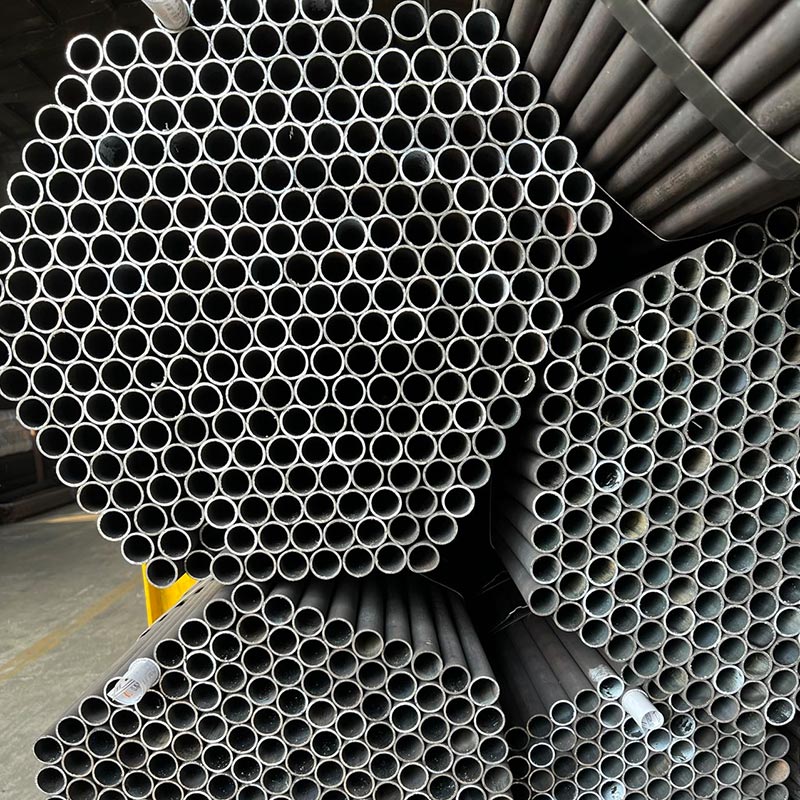

Product detail pictures:

Related Product Guide:

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for OEM Customized Teeth For Front Loader Bucket - Steel tubes for precision application – Xuansheng, The product will supply to all over the world, such as: Turin, Italy, Orlando, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.