Massive Selection for Ea Tooth Bar - Seamless steel tubes for petroleum cracking – Xuansheng Detail:

Seamless steel tubes for petroleum cracking

| Product material |

10/20/12CrMo/15CrMo/12Cr1MoV/12Cr2Mo 12Cr5MoI/12Cr9MoI/ND(09CrCuSb)/08Cr2AlMo |

| Product specification | |

| Product applied standard | GB/T9948-2013 / NB/T47019-2021 |

| Delivery status | |

| Finished products package | Steel belt hexagonal package/plastic film/woven bag/sling package |

Product Manufacturing Process

![]()

Tube blank

Inspection (spectral detection, surface inspection, and dimensional inspection)

![]()

Sawing

![]()

Perforation

![]()

Thermal inspection (alloy steel requires heat treatment)

![]()

Pickling

![]()

Grinding inspection

![]()

Lubrication

![]()

Cold drawing

![]()

Lubrication

![]()

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

![]()

Normalization

![]()

Performance test (mechanical property, impact property, hardness, flattening, flaring, and flanging)

Straightening

![]()

Tube cutting

![]()

Non-destructive testing (eddy current, ultrasonic, and magnetic flux leakage)

![]()

Hydrostatic test

![]()

Product inspection

![]()

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine, sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Outside micrometer, tube micrometer, dial bore gage, vernier caliper, chemical composition detector, spectral detector, tensile testing machine, Rockwell hardness tester, impact testing machine, eddy current flaw detector, ultrasonic flaw detector, and hydrostatic testing machine

Product Applications

Equipment in petrochemical industry and heat exchangers

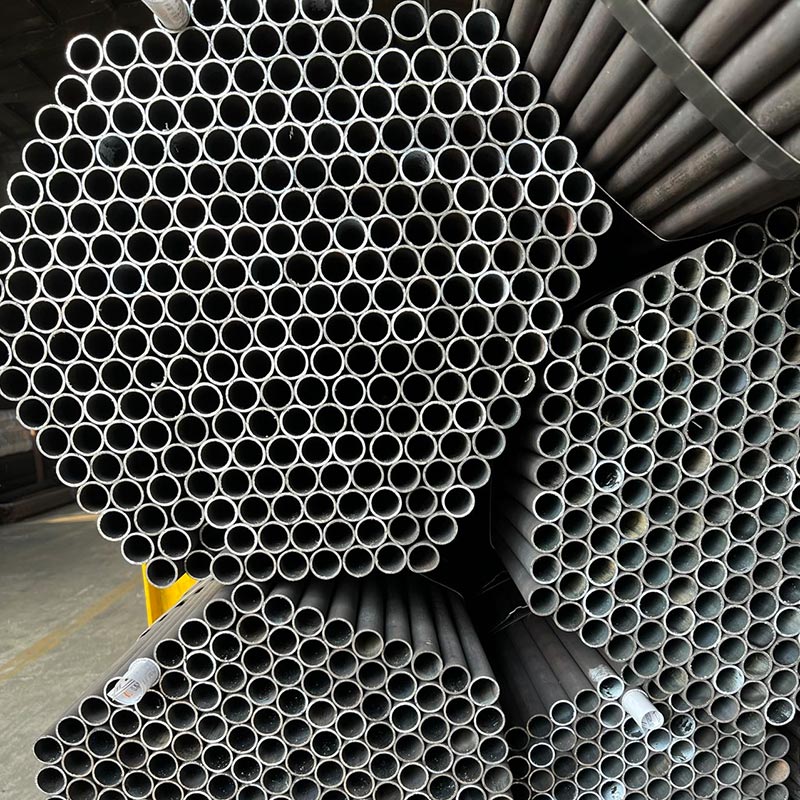

Product detail pictures:

Related Product Guide:

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for Massive Selection for Ea Tooth Bar - Seamless steel tubes for petroleum cracking – Xuansheng, The product will supply to all over the world, such as: Poland, Kyrgyzstan, Cyprus, All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.