Hot sale Factory Excavator Tooth Bucket - CAT330/1U3452RC Caterpillar Tooth Standard Caterpillar bucket teeth – Xuansheng Detail:

CAT330 Bucket Teeth

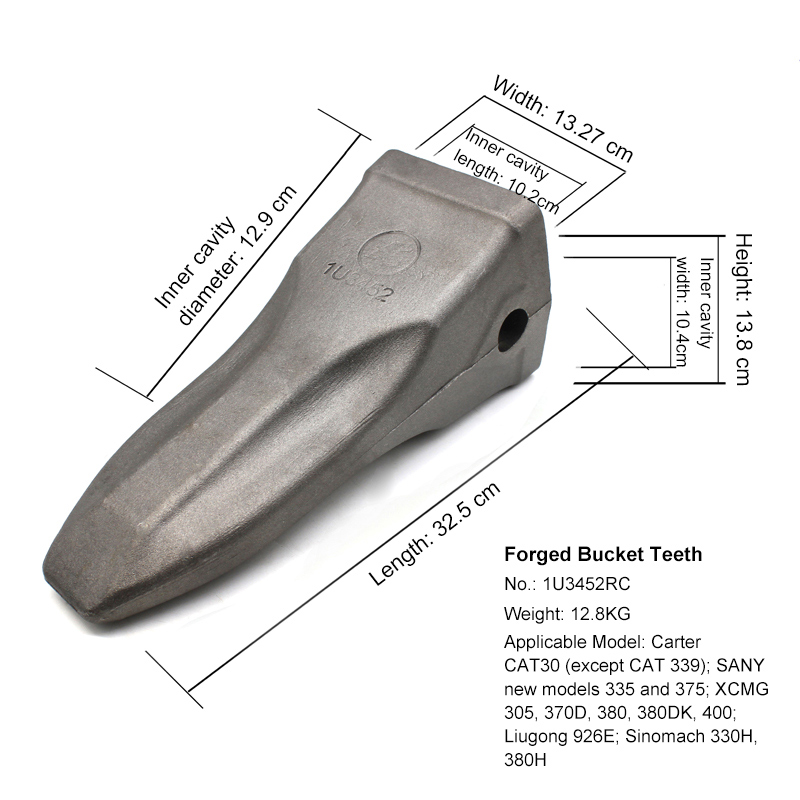

| No. | 1U3452 |

| Applicable model | Carter CAT30 (except new models: 336, 339); SANY new models 335 and 375; XCMG 305, 370D, 380, 380DK, 400; Liugong 926E; Sinomach 330H, 380H; Volvo new model 300; Lovol 390 |

| Product weight (kg/pc) | 12.7 |

| Production status | In production |

●Inner cavity diameter: 12.9CM

●Width: 13.27CM

●Inner cavity length: 10.2CM

●Height: 13.8CM

●Inner cavity width: 10.4CM

●Length: 32.5CM

Product Display

XuanSheng Forged Bucket Teeth Enterprise Features Introduction

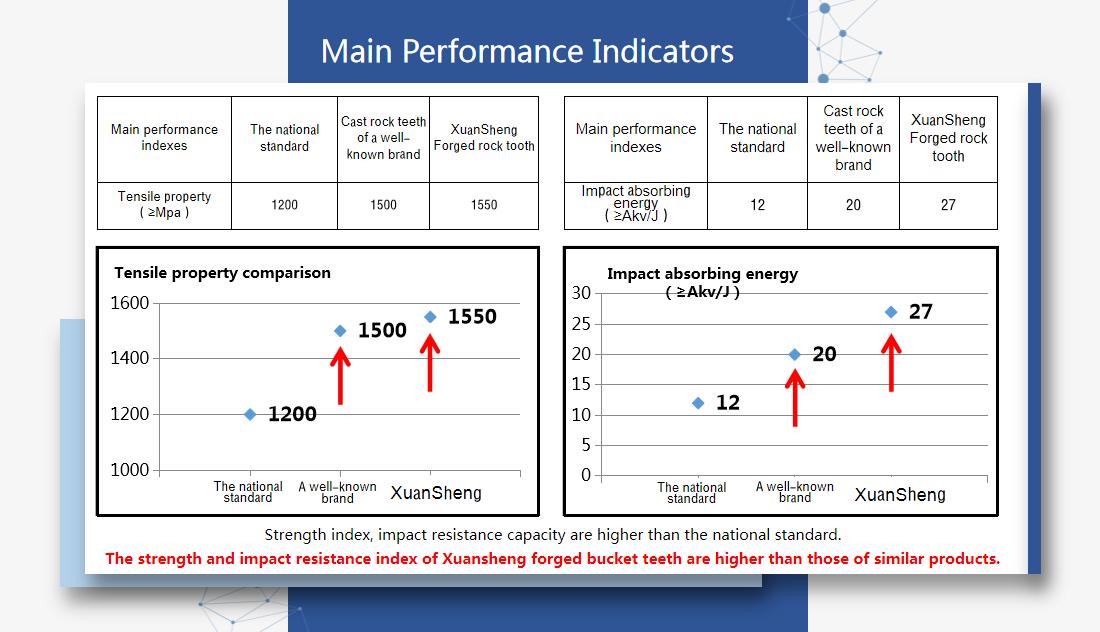

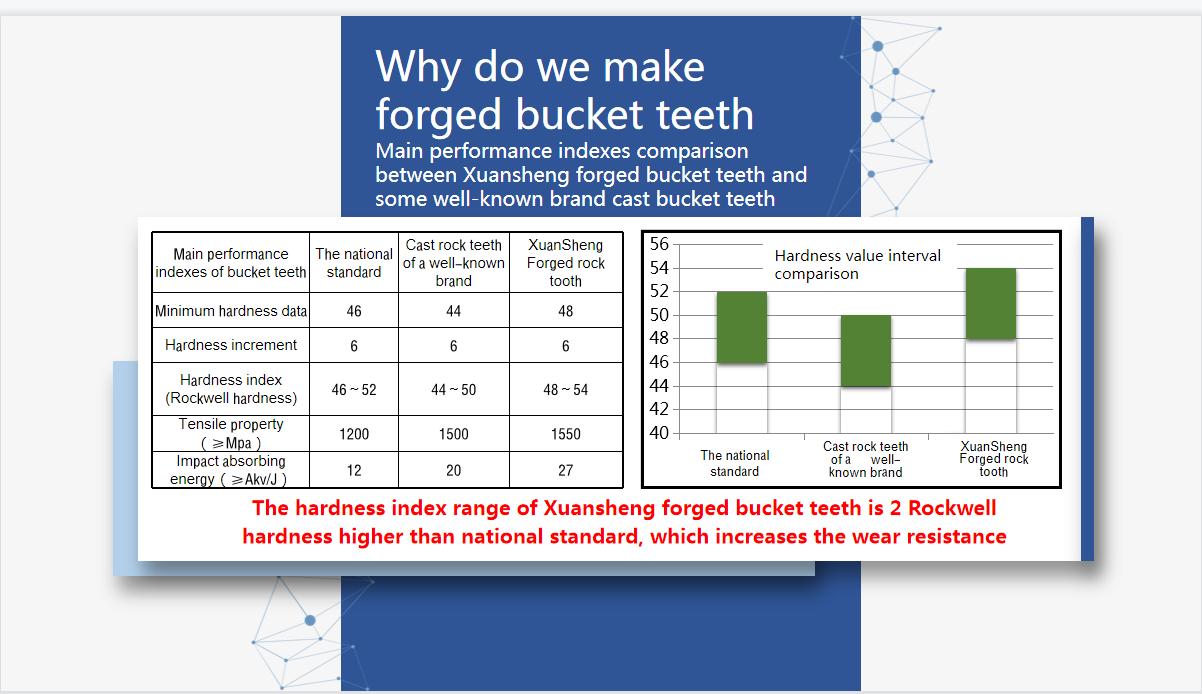

Why do we make forged bucket teeth

Bucket Teeth Manufacturing Process Differences

At present, the common process of bucket teeth on the market

Forging and casting.

Forging

The highest cost, the best workmanship, quality stability and quality of bucket teeth.

Casting

Moderate cost, general raw materials, high level of technology required but poor quality stability (quality each batch varies). The wear resistance of some precision casting teeth is even higher than forging bucket teeth because of ingredients, but the cost is too high.

● At present, the casting bucket tooth is the mainstream product in the market. Forged bucket teeth are in the trend of replacing cast bucket teeth.

Xuansheng Research And Development History Of Forged Bucket Teeth

2016 Raise funds

The first batch of investment exceeded 20 million yuan.

2017 Investment in R & D

The fully automated production line, which adopts new technology and fills the technical gap in China, has started trial production. Raw materials and China’s major steel joint development, special formula steel.

2019 First field test

The field test of Dabaoshan Mine in Shaoguan, Guangdong Province shows that the comparative performance is success.

2020 Combination of production and marketing

The large-scale trial sale was successful, and began to sell all over the country. At the same time, no fracture report was received in the whole year. The quality is reliable.

2021 Further improve performance

On the basis of the mature products in the early stage, it is improved again to further improve the performance and achieve the goal of high cost performance!

Product detail pictures:

Related Product Guide:

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for Hot sale Factory Excavator Tooth Bucket - CAT330/1U3452RC Caterpillar Tooth Standard Caterpillar bucket teeth – Xuansheng, The product will supply to all over the world, such as: UK, Jordan, Turkmenistan, Should any of these items be of interest to you, please let us know. We'll be satisfied to give you a quotation upon receipt of one's detailed specifications. We have our personal experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!