Fast delivery Galvanized Seamless Steel Pipe - Steel tubes for precision application – Xuansheng Detail:

Steel tubes for precision application

| Product material | E215/E235/E355 |

| Product specification | |

| Product applied standard | EN 10305 |

| Delivery status | |

| Finished products package | Steel belt hexagonal package/plastic film/woven bag/sling package |

Product Manufacturing Process

![]()

Tube blank

Inspection (spectral detection, surface inspection, and dimensional inspection)

![]()

Sawing

![]()

Perforation

![]()

Thermal inspection

![]()

Pickling

![]()

Grinding inspection

![]()

Lubrication

![]()

Cold drawing

![]()

Lubrication

![]()

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

Cold drawing/hard +C or cold drawing/soft +LC or cold drawing and stress relieved +SR or annealing +A or normalization +N (selected according to customer’s needs)

![]()

Performance test (mechanical property, impact property, flattening, and flaring)

Straightening

![]()

Tube cutting

![]()

Non-destructive testing

![]()

Hydrostatic test

![]()

Product inspection

Immersion of anti-corrosive oil

![]()

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine/sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Outside micrometer, tube micrometer, dial bore gage, vernier caliper, chemical composition detector, spectral detector, tensile testing machine, Rockwell hardness tester, impact testing machine, eddy current flaw detector, ultrasonic flaw detector, and hydrostatic testing machine

Product Applications

Chemical equipment, ships, pipelines, automotive parts, and mechanical design applications

Seamless steel pipe

Seamless steel pipe (SMLS) is formed by drawing a solid billet over a piercing rod to create the hollow shell, without welding or seam. It is suitable for bending and flanging. The most advantage is increasing the ability of withstanding higher pressure. So it is widely used for boiler and pressure vessel, automotive area, oil well, and equipment components.

Seamless steel pipe can be cut, threaded or grooved. And the coating method includes black / red lacquer, varnish painting, hot dip galvanization, etc.

Cold Drawn Mill:

Cold drawn mill is used for producing small size pipe. There are several times of cold forming process, so yield strength and tensile strength values increase, while elongation and toughness values decrease. A heat treatment must to be applied for each cold forming operation.

Comparing hot rolled pipe, cold drawn pipe maintains precise dimension, smooth surface and shining appearance.

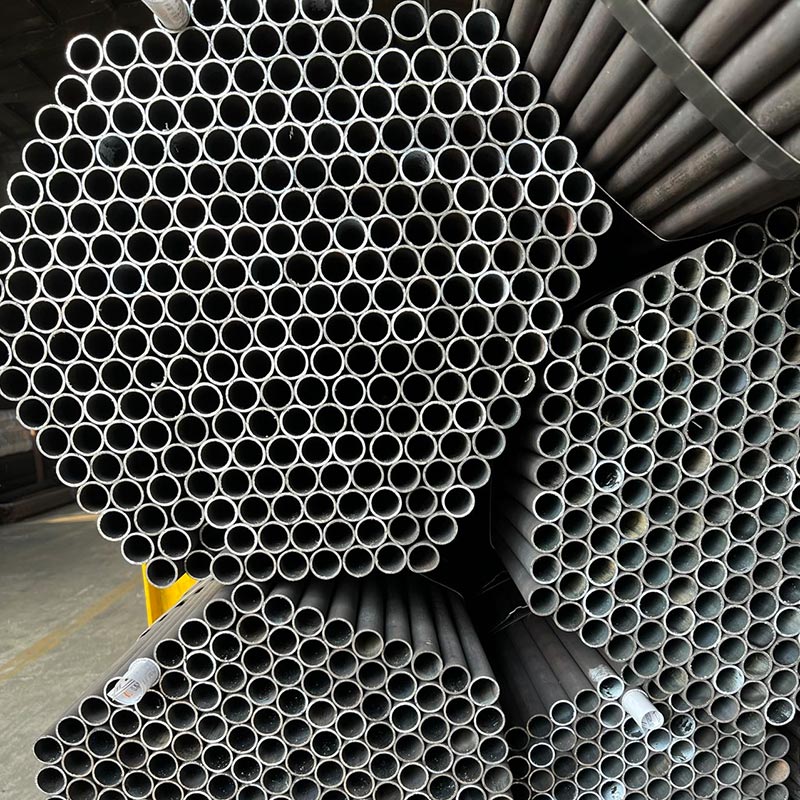

Product detail pictures:

Related Product Guide:

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Fast delivery Galvanized Seamless Steel Pipe - Steel tubes for precision application – Xuansheng, The product will supply to all over the world, such as: Porto, Nicaragua, Detroit, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.