Factory directly Excavator Ripper Shank - Petroleum and natural gas industries-Steel pipe for pipeline transportation systems – Xuansheng Detail:

Petroleum and natural gas industries-Steel pipe for pipeline transportation systems

| Product material | A/B/X42/X46/X52 |

| Product specification | |

| Product applied standard | API 5L |

| Delivery status | |

| Finished products package | Steel belt hexagonal package/plastic film/woven bag/sling package |

Product Manufacturing Process

![]()

Tube blank

Inspection (spectral detection, surface inspection, dimensional inspection, and macro examination)

![]()

Sawing

![]()

Perforation

![]()

Thermal inspection

![]()

Pickling

![]()

Grinding inspection

![]()

Pickling

![]()

Lubrication

![]()

Cold drawing

![]()

Lubrication

![]()

Cold-drawing (the addition of cycled processes such as heat treatment, pickling and cold drawing should be subject to the specific specifications)

![]()

Normalization

![]()

Performance test (mechanical property, impact property, hardness, flattening, flaring, and flanging)

Straightening

![]()

Tube cutting

![]()

Non-destructive testing (eddy current, and ultrasonic)

Spectral detection

![]()

Drift diameter

![]()

Hydrostatic test

Groove

![]()

Product inspection

![]()

Packaging

Warehousing

Product Manufacturing Equipment

Shearing machine/sawing machine, walking beam furnace, perforator, high-precision cold-drawing machine, heat-treated furnace, and straightening machine

Product Testing Equipment

Outside micrometer, tube micrometer, dial bore gage, vernier caliper, chemical composition detector, spectral detector, tensile testing machine, Rockwell hardness tester, impact testing machine, eddy current flaw detector, ultrasonic flaw detector, and hydrostatic testing machine

Product Applications

Pipeline transmission in oil and gas industry

Seamless steel tubes

Seamless steel tubes for general use are also supplied according to chemical composition and mechanical properties and hydrotesting. Seamless steel tubes subjected to fluid pressure should pass the hydraulic test. Special Liaocheng seamless steel pipe for boiler, geological exploration, bearing, acid resistance, etc.

Such as petroleum geological drilling tubes, petrochemical cracking tubes, boiler tubes, bearing tubes, automotive, tractor, aviation high-precision structural steel tubes.

Testing:

1.Observe the logo, specification, factory name and related information on the steel pipe.

2. Check the quality certificate provided by the seamless steel pipe manufacturer.

3.When buying seamless steel pipe, observe whether there are cracks, scars and other hard injuries on the surface of the steel pipe.

4. Observe whether the paint on the surface of the seamless steel pipe is even.

5. In order to avoid purchasing inferior products, try to purchase products from large and well-known brand companies.

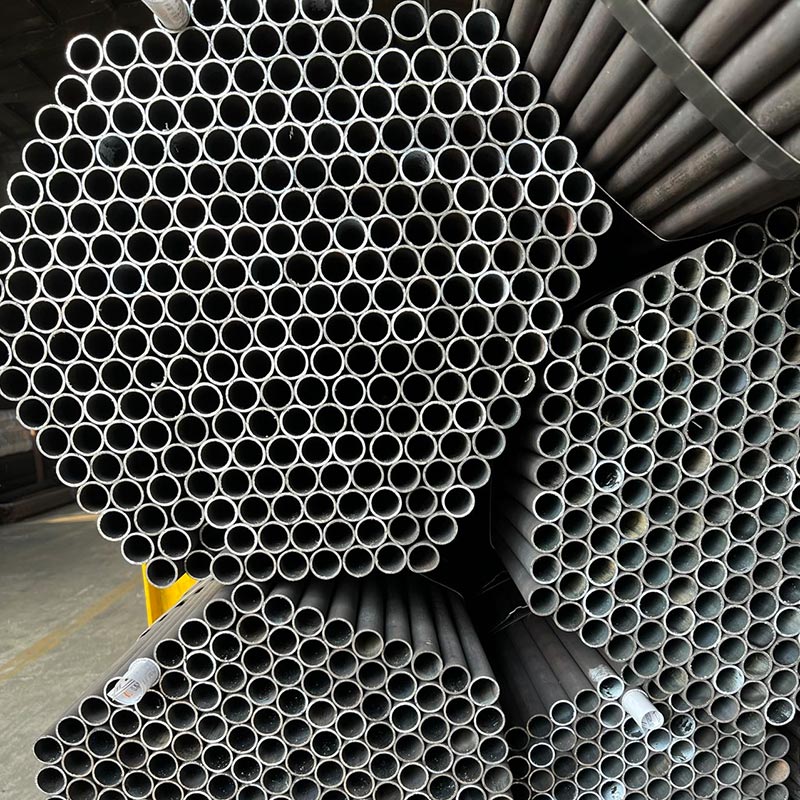

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Factory directly Excavator Ripper Shank - Petroleum and natural gas industries-Steel pipe for pipeline transportation systems – Xuansheng, The product will supply to all over the world, such as: Greenland, Curacao, Eindhoven, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!