Video

DH360 Bucket Teeth

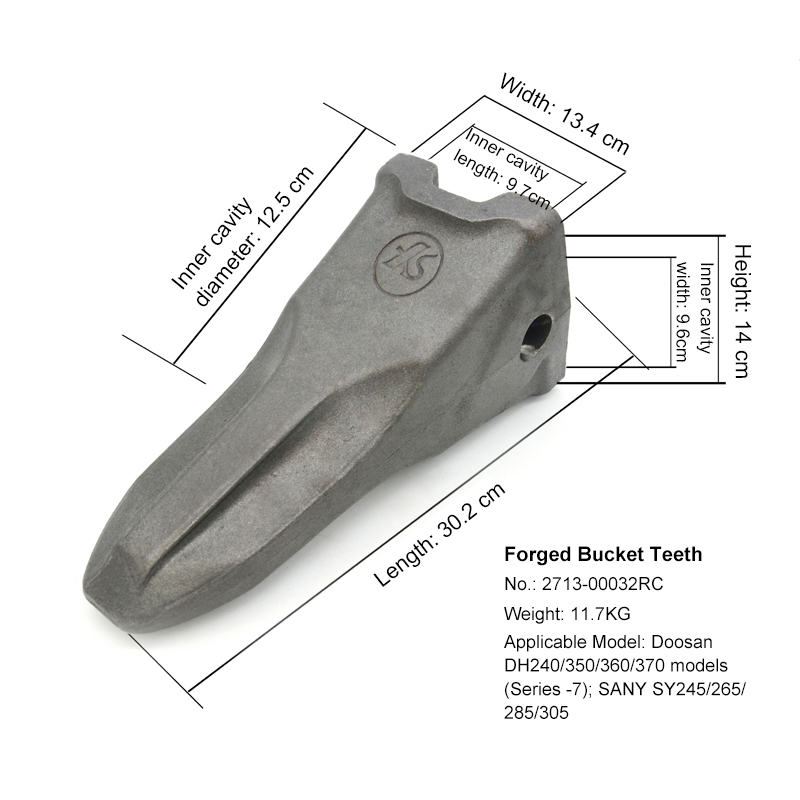

| No. | 2713-00032RC |

| Applicable model | Doosan DH240/350/360/370 models (Series -7) SANY 20 (SY245/265/285/305) |

| Product weight (kg/pc) | 11.7 |

| Production status | In production |

● Inner cavity diameter: 12.5CM

● Width: 13.4CM

● Inner cavity length: 9.7CM

● Height: 14CM

● Inner cavity width: 9.6CM

● Length: 30.2CM

Main Performance Indicators

Main performance indicators: impact energy value, tensile strength, and durability

| Main performance indicators of bucket teeth | China national standards | Cast rock bucket teeth of a well-known brand | Xuan Sheng forged rock bucket teeth |

| Minimum hardness value | 46 | 44 | 48 |

| Increase in hardness | 6 | 6 | 6 |

| Hardness index (Rockwell hardness) | 46~52 | 44~50 | 48~54 |

| Tensile strength (≥Mpa) | 1200 | 1500 | 1550 |

| Impact absorbed energy (≥Akv/J) | 12 | 20 | 27 |

The hardness index range of Xuan Sheng forged bucket teeth is higher than the national standard by more than 2 Rockwell hardness, which increases the wear resistance.

Why Do We Make Forged Bucket Teeth

The Performance Comparison Summary

Forged bucket teeth VS Cast bucket teeth

The first key characteristic of bucket teeth:Not broken!!!

Xuansheng forged bucket teeth:

super strength, fully meet the requirements of mining operations and not be broken.

Main performance indexes: Impact absorbing energy, tensile strength

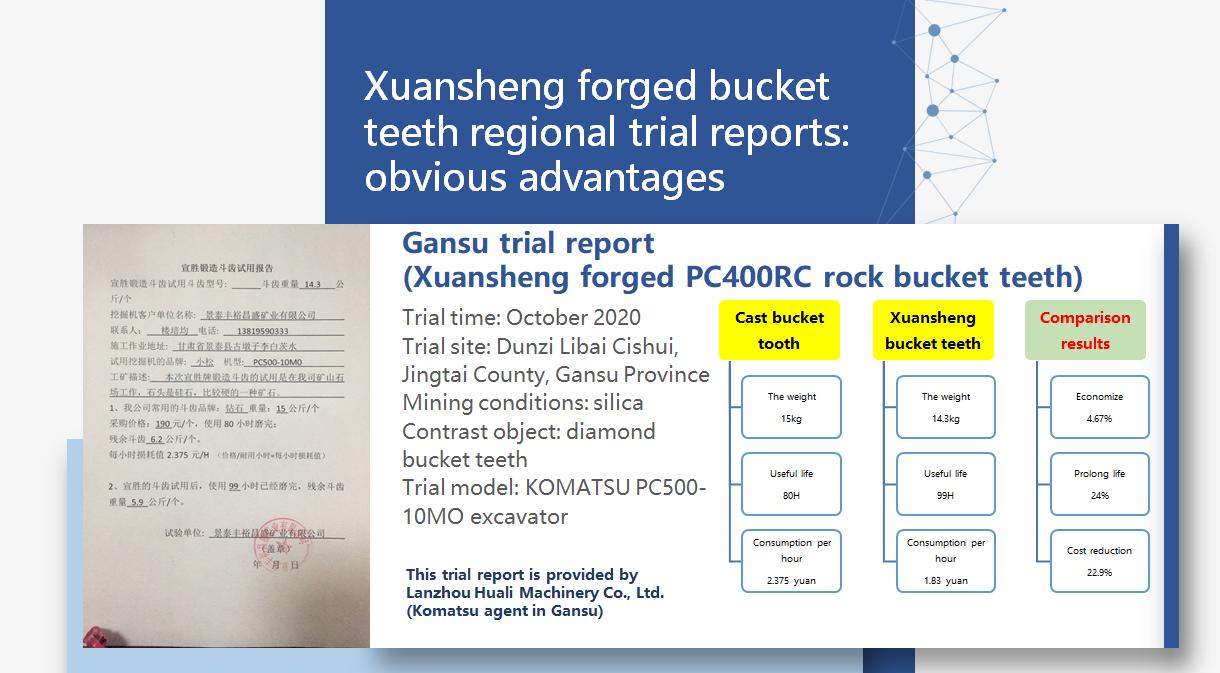

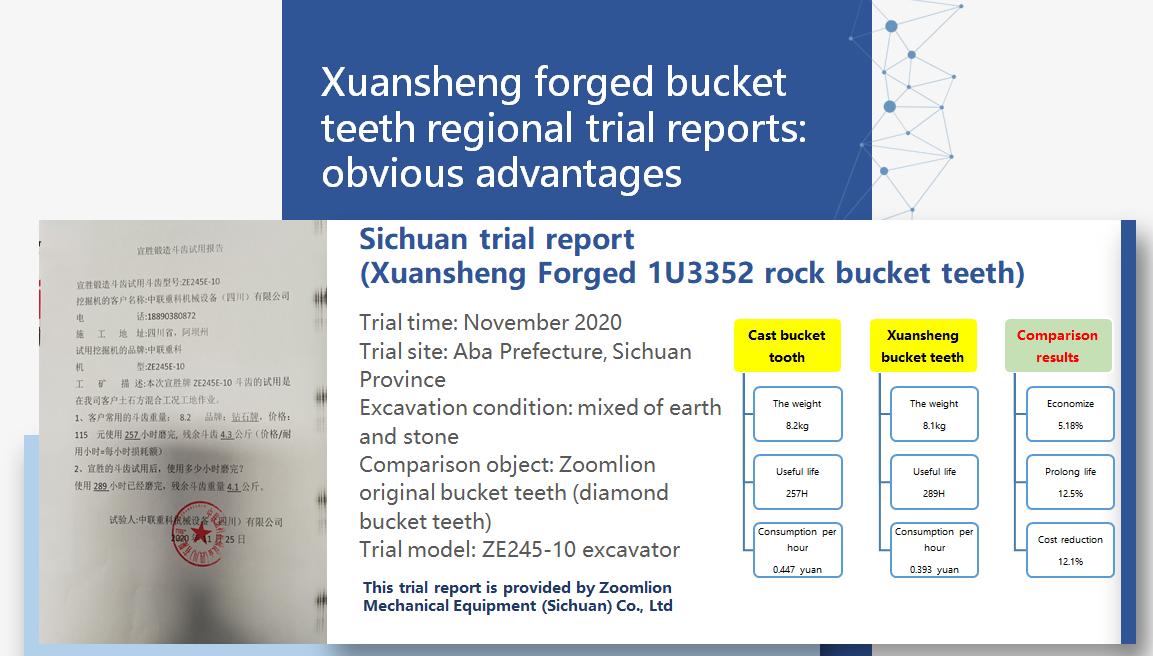

The second key characteristic of bucket teeth:Super economical!!!

Xuansheng forged bucket teeth:

1, the same type of bucket teeth, higher wear resistance

2, Reasonable tooth shape design, sharper, high wearability, less residual

Lower consumption per hour(Lower cost of use)

Here Are Trial Reports From Our Two Of Customers

Features of casting process: melt metal, manufacture casting, molten liquid injection casting, and coagulation casting.

Features of forging process: forging machines are used to apply pressure to heated metal blank to shape it.

Differences between ordinary cast bucket teeth and Xuan Sheng forged bucket teeth:

For the same model of bucket teeth, Xuan Sheng bucket teeth have higher wear resistance, and have reasonable design of tooth shape, which makes bucket teeth sharper, increases wear ratio, reduces residual part, and lowers loss per unit hour (lower cost of use).

Package of carbon steel seamless pipe

Plastic caps plugged at the two sides of pipe ends

Should be avoided by the steel strapping and transport damage

Bundled sians should be uniform and consistent

The same bundle(batch) of steel pipe should be came from the same furnace

The steel pipe has the same furnace number,the same steel gradethe same specification

Caterpillar Tooth Standard Caterpillar bucket teeth

Komatsu Tooth Standard Komatsu bucket teeth